As someone who is trying to "create" my own jig, I was wondering where you got your "design intent". You seem to have really thought the process through, I was wondering what you modeled your jig from, the factory or your own design? (Or posssibly the repair jig in the Boeing SRM?)

For example here is a Boeing jig:

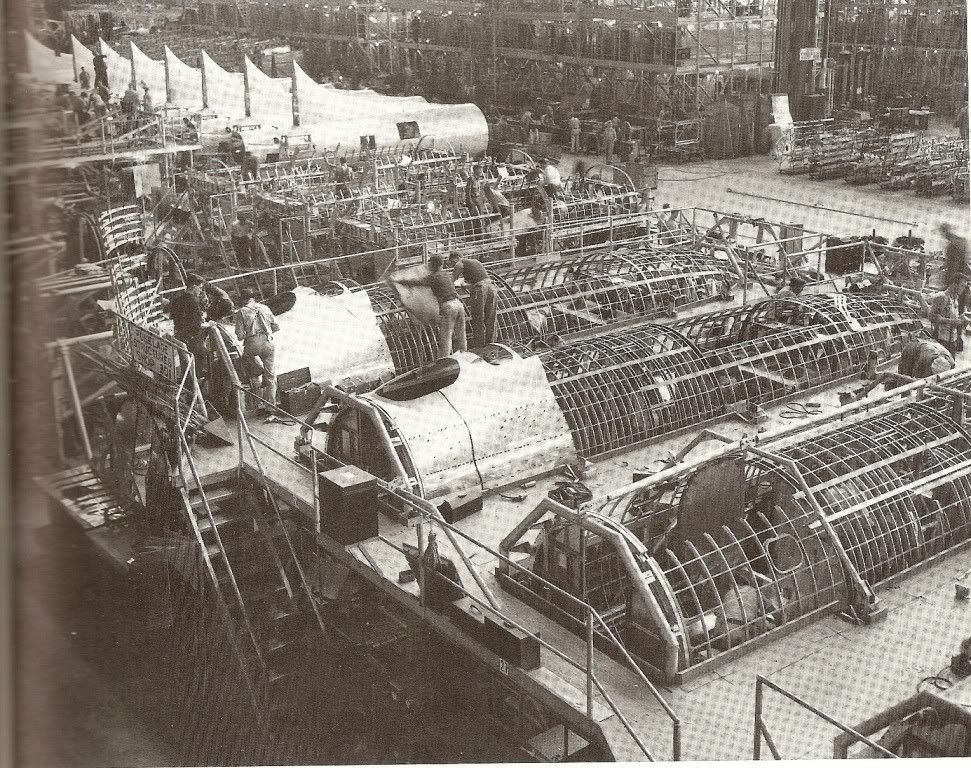

And here is a "after market jig":

Are you using CAD/3D Modeling Software to create the jig before construction?

Here is another "after market" jig design using CAD:

And the finished product:

Thank you for posting your hard work, this looks like a well planned effort!